Our Expertise:

At the house of

GCER, our excellence lies in the ability to accurately size your equipment, resulting from a thorough analysis of your specifications and requirements. We are committed to designing each piece of equipment to optimally withstand specific constraints such as temperature, pressure, vacuum, chemical aggression, earthquakes, snow and wind. These requirements are rigorously integrated into our design process.

Our design office is fully equipped to develop the construction plan for each order, based on your master plan or instructions, in order to obtain your approval before manufacturing.

Analytical Calculations:

GCER

provides detailed analytical data on your equipment, in line with your needs. We perform analytical calculations in accordance with global standards for GRP fiberglass for tanks. These calculations take into account parameters such as specific gravity, temperature, climatic conditions (wind, snow, earthquake), and other customer-specific criteria.

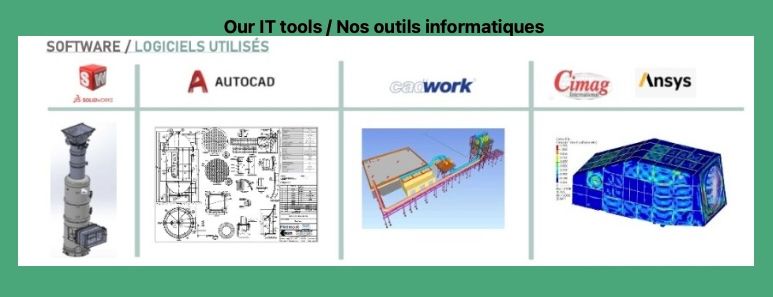

Stress Analysis and FEM Analysis:

At the customer's request, GCER performs FEM analyses on fiberglass or metal components integrated into tanks, piping and metal structures. Our construction plans are developed in CAD, in accordance with international standards and using software such as EN/ASME/BS/DIN/NF/ASTM/AWWA/DVS, AUTOCAD/ABAQUS/SOLIDWORKS/CADWORKS/PV ELITE/CAESER/TEKLA.

Industrial Piping Testing:

We conduct tests upon receipt of raw materials to ensure they meet the required specifications. Our tests comply with global standards such as ASTM, ISO, DIN, NF, EN, etc. They include tensile, bending, compression, shear, hydraulic pressure, vacuum, MTP/SVR, concrete/SVR, steel separation tests, etc. Chemical tests and loss on ignition tests are also performed.

Information on our ATEX manufacturing

Dry assembly on a flat slab of equipment and frames, carried out in our GCER workshops to validate their conformity and their future installation on site.